Creative Problem Solving at NHS Coventry

When working the Unipart way, colleagues are encouraged to work together to solve problems at their own level. This approach will often drive down costs and increase productivity, adding value for our customers and/or making the job easier for colleagues.

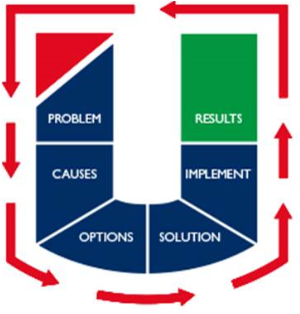

One of the core tools of the Unipart Way is that of Creative Problem Solving (CPS). The OCC Circle (Our Contribution Counts) is the mechanism whereby a team of colleagues work together to follow a logical six-step approach to creative problem solving: the Unipart CPS-U.

Colleagues at the NHS Supply Chain site in Coventry completed 5 OCC circles last month, and certificates were presented at a ceremony conducted by OCC Champion Brian Cowling on Friday last week.

Size Matters

The first OCC circle tackled a safety issue with pallets being stacked higher than the 1.8m limit.

Visual Management was used to help pickers to avoid over-stacking pallets, and a measuring device was introduced to ensure that all pallets comply with Health & Safety guidelines, keeping colleagues safe.

Social Distancing

Supported by the Health & Safety lead for the Coventry site, another circle helped to set a standard approach to the visual management and control documents used to ensure social distancing.

Signage and one-way systems were introduced, and Covid-19 audits are being carried out regularly, highlighting good behaviours and any areas for improvement.

Space Invaders

This circle introduced a new layout for the cross-dock area.

Using Visual Management to ensure that temperature-controlled pallets are more easily identified, and can be moved quickly into a temperature-controlled container, avoiding any breach of our customer’s requirements and protecting product quality.

Back to the Future

This circle introduced a new digital tracking system in the Inbound Logistics area, replacing a number of processes previously using whiteboards or Excel spreadsheets.

With Google sheets displayed on screens in the office, the new control board enables the Transport team to communicate with the warehouse, detailing what needs to be loaded or unloaded and to archive this data.

The Transport team has also digitised the yard parking control boards to give real-time tracking of what is where, and created a new vehicle servicing and MOT document that gives a 2 weekly view of what is due.

Driver Recruitment

As part of the TUPE transfer to Unipart in February 2019, NHS Inbound Logistics acquired just 5 full-time drivers.

For the first 8 months of the contract they had to rely heavily on agency resources. Towards the end of 2019, the team set themselves a target of taking on 10 more drivers on a permanent basis both to provide greater control over working hours and to achieve cost savings or around. £122k p.a.

But the team didn’t stop there: they now have 25 drivers permanently employed and 2 more currently working ‘temp to perm’. The savings are now expected to reach around £254k p.a. or close to £1 million over the contract period.

Delighted to see the significant financial impact they have had by working together to find a creative solution to this one problem, the team is already planning their next OCC!

"Despite the pressures and changes which Covid-19 has brought, the team at Coventry has used the OCC and creative problem solving tools to engage colleagues and deliver real benefits. Not only was it truly inspiring to learn from our leaders and colleagues first hand just what they have delivered, but I was pleased to hear how they found the whole experience of working with the tools. It is the unambiguous leadership from the site team led by GM Dave Collins which is making the difference, as the many benefits of the Unipart Way and application of digital become apparent."

1 comment has been posted.

July 10, 2020, 7:27 a.m. - Andy Pyne ¶