Black Belt Joe

Joe Clutton attributes his recently-acquired Six Sigma Black Belt to his role in Unipart’s digital transformation.

“I completed my Black Belt by supporting the Group's digital movement through my work as a digital champion at the Baginton site,” said Senior Operations Manager Joe.

“The Black Belt skill set around changing management and working within cultures was really beneficial in being able to understand how I could have shifted that culture, moving a traditional site into the digital agenda.”

Currently work package lead for Project Mercia, the huge Unipart Logistics contract with Jaguar Land Rover announced last year, Joe joined the company on a graduate scheme in 2016 and took on a number of placements over the next two years.

He immediately became interested in Six Sigma, which he defines as: “A methodology and a way of working that always puts the customer first and improves quality and consistency."

Joe achieved his Six Sigma Yellow Belt within weeks of joining the business by attending a one-day training and awareness session, to gain a better understanding of the methodology and its uses within Unipart. And he didn’t stop there.

“I’d just started a six-month placement at the Waterstones site in Burton when I began my Green Belt. There, I identified a problem with the inbound process - stock did not fit into their correct locations. I used my Green Belt training to understand what was causing the issue and reduced the problem.”

Like everyone who has achieved Six Sigma Black Belt, Joe had to complete around 30 days training across 18 months, followed by a series of tasks around the 12 specific competencies of Six Sigma, ranging from project management to leadership to working with customers.

Joe said: “I was part of a team who ended up generating more digital ideas than any other site in the Group. Then I was awarded my Black Belt in October 2021 after finishing my evidence over the summer.”

Joe believes Six Sigma is an enormous benefit to the business. He said: “Having a wide spread of Six Sigma skills at all levels enables the business to make data-driven decisions. It empowers the person to question what is happening and support critical thinking and decisions and keep that business on a data-driven path.”

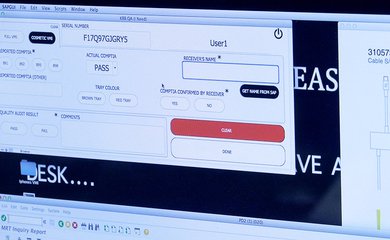

In May 2021, Joe took on his most recent role implementing the warehouse management system and designing process for the new 2.94m square feet Jaguar Land Rover Appleby Magna site (pictured, right).

“My Yellow, Green, and Black Belt training, and all the skills I’ve learnt from Six Sigma have really supported my career trajectory, with being able to deliver what I’ve done, and get to where I have today.”

You can book upcoming dates for Six Sigma workshops on Unipart Way Online, provided you have your line manager’s approval. Send an email to Master Black Belt Sue Christelow on sixsigma@unipart.com when you are ready to book your place.

Find out how Six Sigma-trained colleagues can support your operations and how they help facilitate Our Contribution Counts circles.

3 comments have been posted.

Jan. 19, 2022, 7:14 p.m. - Ashok Gohil ¶

Jan. 19, 2022, 1:21 p.m. - Denny Sharman ¶

Jan. 19, 2022, 9:58 a.m. - Joanna Matson moderator ¶